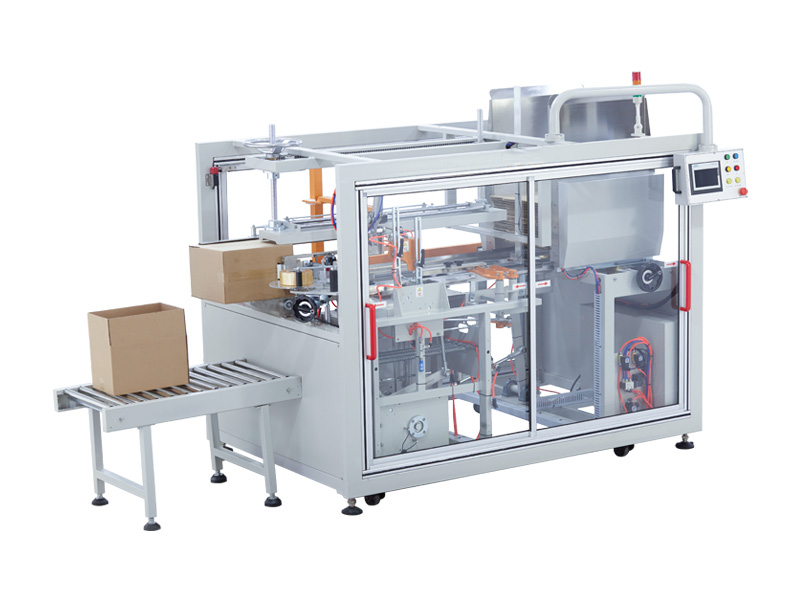

The automatic case erecting machine is one of the back-end packaging automation equipment, which can complete packaging procedures such as carton suction, unboxing, forming, folding, and sealing in one go. It has stable performance, high efficiency, beautiful and firm sealing and opening effects. But recently, some customers have reported that there may be some malfunctions when using automatic unboxing machines, and they do not know how to solve them. In order to solve everyone’s problems, Gu Erqi’s editor will introduce the common faults and solutions of automatic unboxing machines:

Fault 1: The automatic case erector packing machine absorbs vacuum from the cardboard box, and the vacuum time for the lower solid box is long enough?

Solution: At this point, we need to check the circuit, air circuit, solenoid valve, and vacuum generator one by one, and readjust the parameter settings.

Fault 2: When the Case Erecting Case Packer is working, does the rising cylinder of the lower solid box not move or does it move very slowly?

Solution: It is necessary to accelerate the cylinder regulating valve, and if it is not possible, replace the solenoid valve.

Fault 3: suction cup malfunction, damaged suction cup or insufficient air pressure

Solution: Replace with a new product or adjust the air pressure.

Fault 4: Abnormal tape applicator

1. The tape cuts continuously.

Solution: The blade is no longer sharp or the tape film is stuck at the blade tip. Replace the blade, wipe it clean, and apply oil.

2. The tape has been cut but dragged one section.

Solution: The knife holder is stuck, and the action is not flexible or the spring is not tight enough. Check the screws at various parts of the tape applicator or adjust the tension of the tension spring.

3. The tape was cut but did not adhere to the box surface.

Solution: The main tension spring is too loose, and the rebound speed of the rear wheel cannot match the belt speed. Moderately tighten the main tension spring screw.

4. The cardboard box got stuck in the middle.

Solution: The main tension spring is too tight and the front wheel is stuck in the middle. Moderately loosen the main tension spring of the belt wheel.

5. The tape is prone to detachment.

Solution: The one-way roller loses its effectiveness, replace it with a new one-way roller.

Post time: Jun-26-2023